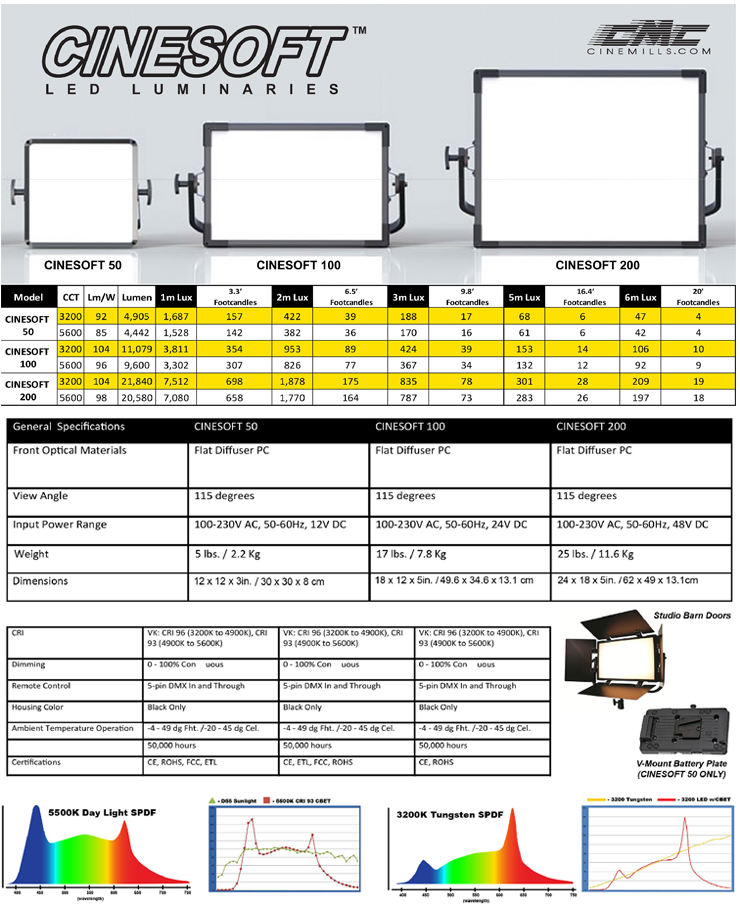

PRODUCT

Emperical Data supporting the CINESOFTS

Distinct Advantage Over Competing Fixtures.

THE CINESOFT 50,100 & 200 BY CINEMILLS OUTPERFORM THE COMPETITION.

TO UNDERSTAND WHY WE MUST FIRST UNDERSTAND LED PERFORMANCE METRICS

AS IT RELATES TO CAMERA IMAGING.

THE CORE FOUNDATION OF LED QUALITY

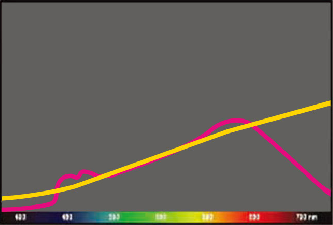

1. Spectral Power Distribution Function("SPDF")

2. CRI (Color Rendering Index)

3. Delta UV for the Camera lmage

The above (SPDF, CRI & Delta UV) represent the three most important aspects as it relates to lighting

quality as renderd onto a Cameras lmage.

1. SPDF translates directly to the color fidelity of the image captured by a camera.

2. CRI (Color Rendering Index) describes the color fidelity of the image as per the human eye

According to Science & Technology Council of the Academy, CRI of the lighting systems for the

motion picture camera is a fact of "Necessary Condition" , but not a "Sufficient Condition"

because of the different spectral response of the motion picture cameras and the human eyes.

3. Delta UV describes how much the white light from a lighting source is as close to the white

spectrum from the Sun also referred to as "black body radiator." This has a direct effect on the

green/magenta cast. The recommended Delta UV is between -0.002 and 0.002 in order to

minimize the green/magenta cast from the lighting.

* SPDF relates to color fidelity captured by a camera, High CRI 90+ is also important

* CBET (Color & Brightness Enhancement Technology) inside Cinesoft product makes it happen!

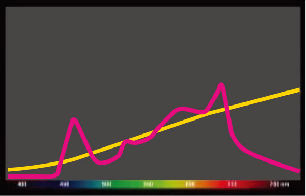

Pink line : The ideal, imagery of SPDF of a 3,200K LED

lighting system as suggested by the Science & Technology

Council of Academy (Currently, There is no LED lighting

with this ideal SPDF)

Yellow Line : The SPDF of a 3,200k Tungsten Halogen

light source

Upper colors : Captured by a camera under

3,200k tungsten halogen.

Lower half colors : Simulated colors captured

by a camera under the ideal 3,200k LED lighting-

simulated by Science&Technology council of

the academy

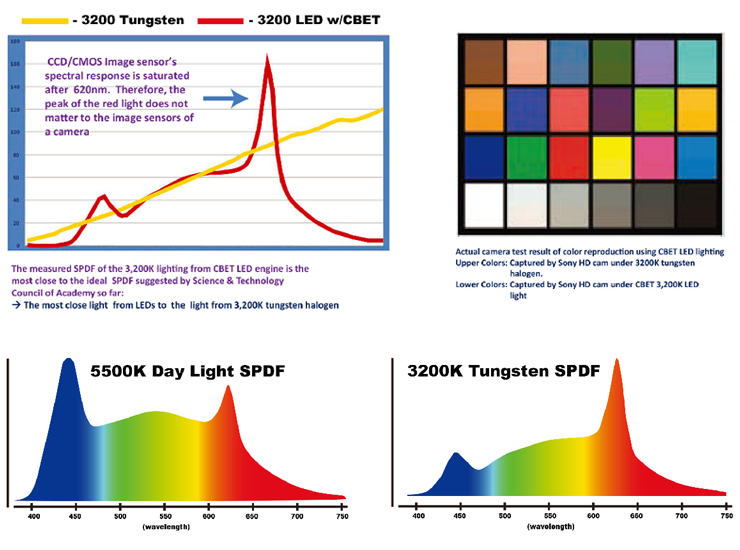

Pink line : The SPDF of 3,200k LED lighting system

with CRI > 95

Yellow Line : The SPDF of 3,200k Tungsten Haloge

Upper colors : Captured by a camera under

3,200k tungsten halogen.

Lower half colors : Colors captured by a camera

under 3,200k LED lighting with the SPDF shown

colors are different from the colors under

3,200k tungsten halogen because of

the different SPDF.

* SPDF relates th color fidelity captured by a camera, High CRI 90+ is also important

* the image sensors used for digital camera is based on 2 structures, 3panels

with optical color separation prism or 1 panel Bayer color filter :

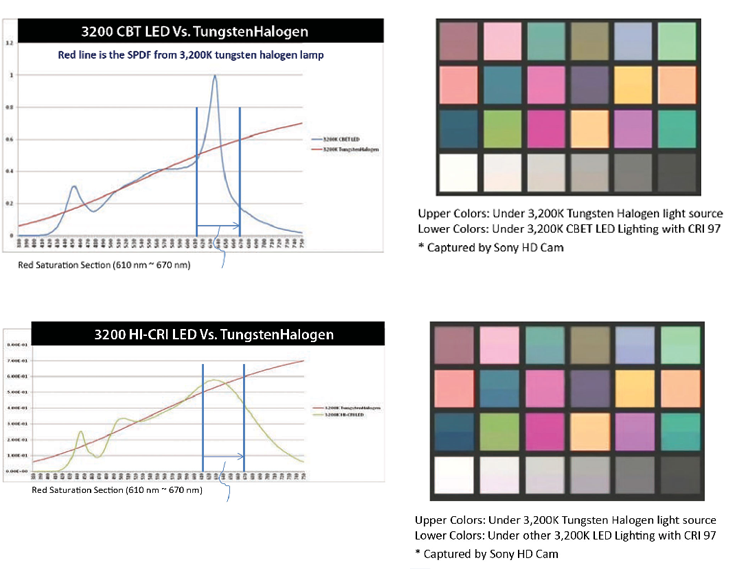

1.Color & Brightness Enhancement Technology (CBET)makes the SPDF of the CINESOFT 50,100

& 200 with CCT, 3,200K the closest replication of SPDF from the light emitted from a 3,200K

Tungsten Halogen Fixture.

2.The SPDF of 5500K light from the CINESOFT LED lighting products is also relatively most closest

to the sun light in its 5,500K (llluminant D55) setting compared to any other LED products.

→ The best color fidelity can be achieved using LED lighting products along with digital cameras.

→ Less time and money for required for DI (Digital Intermediate ) Color Correction during post

production as a result of using the CINESOFT products.